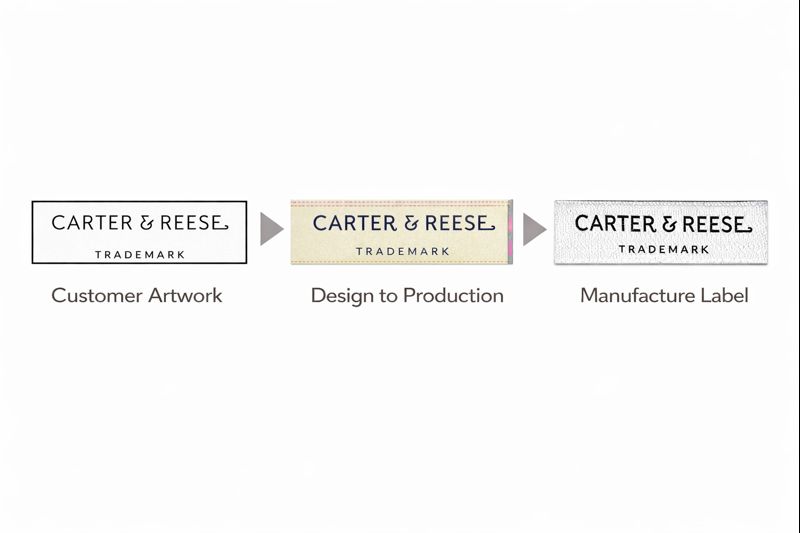

Our Manufacturing Process

From initial artwork submission to finished product delivery, our streamlined 3-step process ensures consistent quality and precision. See how we transform your brand vision into premium woven labels.

Customer Artwork

Send us your logo or design in any format. We preserve your brand's original look and proportions while preparing it for production.

Design to Production

Our factory team digitizes your artwork with precision thread mapping and color separation for perfect weaving reproduction.

Manufactured Label

Labels are woven on industrial looms, then cut and finished to your exact specifications with professional quality control.

Our Complete Manufacturing Process

Step 1: Customer Artwork

Your journey begins with submitting your brand artwork to our team. We accept files in various formats including AI, PDF, SVG, and high-resolution PNG or JPEG files.

- Vector files preferred for crisp reproduction

- Color specifications and Pantone matching available

- Multiple size variations supported

- Design consultation included at no extra charge

Step 2: Factory CAD Digitizing

Once your artwork is approved, our skilled technicians convert it into precise manufacturing specifications using advanced CAD software. This critical step ensures perfect reproduction of your design in the woven format.

- Precision thread mapping for accurate reproduction

- Color separation for multi-thread weaving

- Size and fold specifications programming

- Quality checkpoints throughout the process

Step 3: Woven, Cut, and Finished

Using state-of-the-art equipment in our California facility, we produce labels that meet the highest quality standards. Each label undergoes multiple quality inspections during production to ensure consistent color matching, proper fold alignment, and clean edge finishing.

- High-speed precision weaving equipment

- Ultrasonic and heat cutting for clean edges

- Multiple fold options: end fold, center fold, or flat

- Custom packaging and labeling available

Why it works

We manage the entire process in-house, from design preparation to final production. This means fewer errors, better quality, and consistent results every time.

Ready to Start Your Project?

Send us your artwork and specifications to begin the process. Our team will guide you through each step and ensure your labels exceed expectations.